Manufacturing, relocation

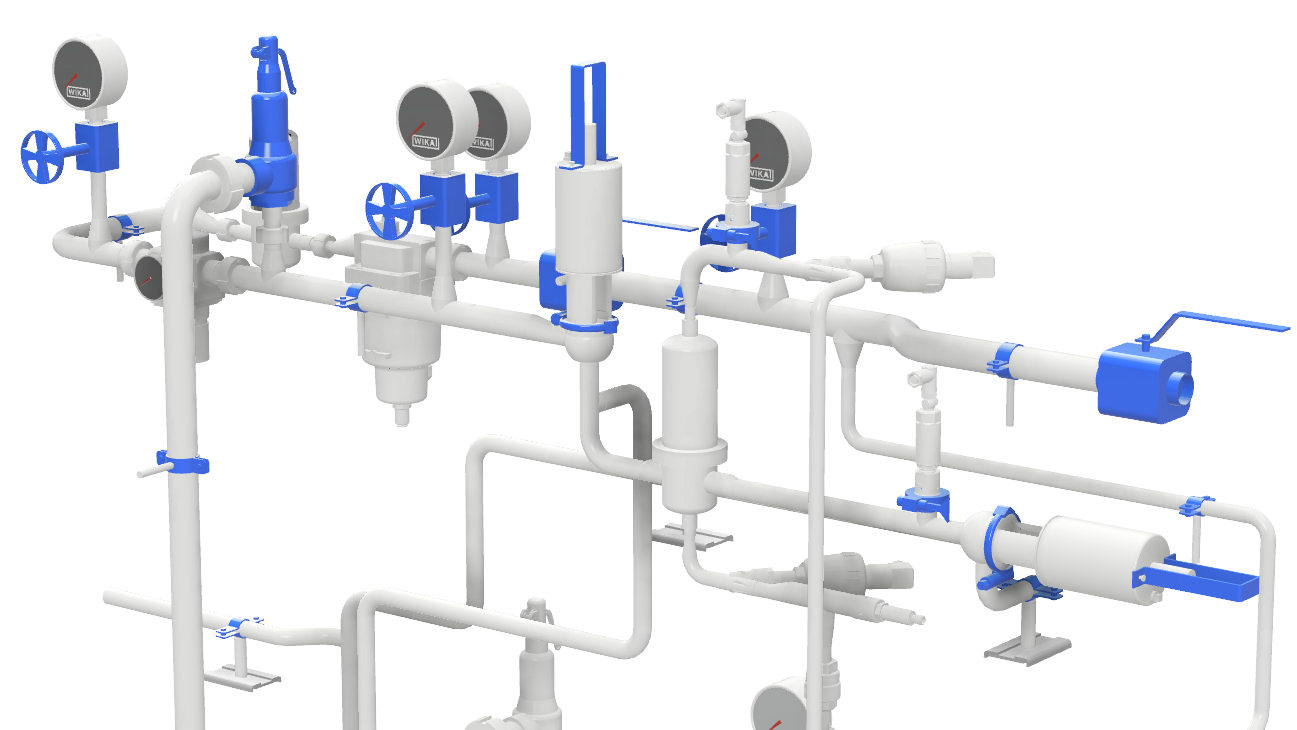

installation of industrial equipment

installation of industrial equipment

For food, chemical and metallurgical industries

Company founded in 2000 as a manufacturer of spare parts for units, machines, heavy machinery equipment.

О компании

In 2002, the company split into construction and production divisions.

Production Division - MEKAT

Production hall and office

Construction Division - ARKA

Shop for the manufacture of non-standard metal structures

The basis of the company is highly qualified personnel and team approach to problem solving. Any task is considered as a separate project. within which a team of the company's personnel is formed: project engineers, designers, installers, riggers, welders, electricians.

The basis of the company is highly qualified personnel and team approach to problem solving. Any task is considered as a separate project. within which a team of the company's personnel is formed: project engineers, designers, installers, riggers, welders, electricians.

Services

business areas

Development and production of non-standard equipment, improvement of efficiency of the equipment in operation. Production of spare parts for the supplied equipment. Design and supply of metal platforms and products. Design and supply of packaging for industrial equipment.

Installation, modernization of equipment at the customer's site. Installation of turnkey technological lines, installation of pipelines and engineering systems. Development and modernization of software.

Turnkey movements of individual pieces of equipment and complex technological lines, including dismantling, packing, loading, including international road and air transportation.

Services

business areas

Development and production of non-standard equipment, improvement of efficiency of the equipment in operation. Production of spare parts for the supplied equipment. Design and supply of metal platforms and products. Design and supply of packaging for industrial equipment.

Installation, modernization of equipment at the customer's site. Installation of turnkey technological lines, installation of pipelines and engineering systems. Development and modernization of software.

Turnkey movements of individual pieces of equipment and complex technological lines, including dismantling, packing, loading, including international road and air transportation.

Projects

For more than 15 years, the team of designers and installers has gained enormous experience in construction, reconstruction and modernization of various objects of any level and complexity.

Technology development, production and installation of a mixing line,

formulation and packaging of polymer processing additives in a controlled atmosphere.

Project development and equipment supply was realized in ATEX version.

formulation and packaging of polymer processing additives in a controlled atmosphere.

Project development and equipment supply was realized in ATEX version.

Design and installation of pneumovacuum complex for unloading chemical raw materials from rail cars of HOPPER type. Replacement of water ring vacuum pumps with blowers.

Development of technology, design, production and installation of equipment for preparation of complex food flavoring additives.

Increasing the degree of sterility of the fermentation process and storage of milk mixtures. Elimination of "dead" zones, drying of pipelines after CIP washing. Delivery of sterile air and cooking steam module.

Audit, dismantling, container packing with veterinary certification, sea transportation, assembly and start-up of a complex syrup production line with additional equipment for sugar melt, CIP washing, pasteurization.

Design, procurement of equipment, installation of central vacuum distribution system of cigarette shop

Projects

For more than 15 years, the team of designers and installers has gained enormous experience in construction, reconstruction and modernization of various objects of any level and complexity.

Technology development, production and installation of a mixing line,

formulation and packaging of polymer processing additives in a controlled atmosphere.

Project development and equipment supply was realized in ATEX version.

formulation and packaging of polymer processing additives in a controlled atmosphere.

Project development and equipment supply was realized in ATEX version.

Design and installation of pneumovacuum complex for unloading chemical raw materials from rail cars of HOPPER type. Replacement of water ring vacuum pumps with blowers.

Development of technology, design, production and installation of equipment for preparation of complex food flavoring additives.

Increasing the degree of sterility of the fermentation process and storage of milk mixtures. Elimination of "dead" zones, drying of pipelines after CIP washing. Delivery of sterile air and cooking steam module.

Audit, dismantling, container packing with veterinary certification, sea transportation, assembly and start-up of a complex syrup production line with additional equipment for sugar melt, CIP washing, pasteurization.

Design, procurement of equipment, installation of central vacuum distribution system of cigarette shop

Contacts

LLP TECHNO ARKA

Republic of Kazakhstan, Astana

Теl: +7 (702) 028 12 45

Internet: www.arcateh.com

E-mail: info@arcateh.com

Republic of Kazakhstan, Astana

Теl: +7 (702) 028 12 45

Internet: www.arcateh.com

E-mail: info@arcateh.com

Installation and relocation of industrial equipment